1. INTRODUCTION

The reduction or replacement of saturated fat from foods may result in serious and undesirable changes in physical and sensory characteristics of the final products (Gao et al., 2024). The nutritional recommendations from international health organizations have consistently emphasized the need to minimize the excessive consumption of trans and saturated fatty acids and replace them with healthier alternatives (Paliwal & Wan., 2024). Therefore, food manufacturers are trying to decrease or eliminate such solid fats, which would encourage the oil substitutes prepared using different new technologies. Although unsaturated fatty acids have various health benefits over solid fats, food products without solid fats do not provide the desirable properties. A novel and promising technology for reducing saturated animal fat and improving the nutritional profile of food products is replacing it with edible oleo gels. Oleo gelation has been proposed as an alternative method for converting liquid vegetable oils to hard stock structures that resemble the properties of conventional fat (Manzoor et al., 2022). The most promising and novel alternative to these fats is the structuring of oil with the help of oleogelation. Such structures can entrap above 90% liquid oil in a three-dimensional network at very low concentrations (1–10%). Oleogelation neither changes the unsaturated profile nor uses chemicals to convert the liquid oil into gel networks (Zhao et al., 2020), thereby minimizing the harmful effects of saturated fats and providing the nutritional benefits of unsaturated fats. Several food-grade materials such as proteins, polysaccharides, fatty acids, and phytosterols can be used as oleogelators depending on the desired physical characteristics and applications in particular food systems. Oleogels also produce heat-resistant products and help combat the challenge of oil leakage in various products. Other significant application of oleogels lies in their ability to act as carriers for lipophilic bioactive substances. Recently, oleogels were applied in the deep frying of noodles, thus minimizing the chances of trans-fat production as deep frying is also a potent source of trans-fatty acid production (Mahmud et al., 2023).

Medium-chain triglyceride (MCT) oleogels have improved thermal and oxidative stability, making them ideal for formulations with a longer shelf life (Jadhav et al., 2022). The gel structure of MCT oil creates a smooth and desirable texture, improving mouthfeel in food products and the application of creams and lotions in cosmetics. Furthermore, MCT oleogels can encapsulate bioactive compounds, flavors, and nutrients, making them useful for the development of functional foods and nutraceuticals (Gengatharan et al., 2023). MCT oleogels are healthier alternatives to traditional fats in the food industry, especially in spreads, dressings, and confections, allowing for lower saturated fat content while maintaining desirable textures.

Additionally, MCT oleogels act as carriers for active pharmaceutical ingredients in the pharmaceutical sector, enhancing bioavailability and stability (Pawar et al., 2024). β-carotene has a strong antioxidant capacity and high provitamin A activity, which is why it is the most important member of the carotenoid family. β-carotene intake has been shown to improve the immune system’s response to infections and reduce the incidence of certain chronic diseases. Humans cannot synthesize β-carotene in their bodies, and so they must obtain it from the foods they consume. Nowadays, waxes, including carnauba, candelilla, rice bran, and beeswax, are used to prepare oleogels and in various food applications. Beeswax provides various antioxidant properties that help protect against various types of infections (Fratini et al., 2016), and the rapid absorption of MCTs provides a quick energy source that supports metabolic function (Watanabe & Tsujino, 2022). Additionally, both ingredients possess anti-inflammatory effects, contributing to improved skin health. Mixing MCT oil with beeswax and enriched with β-carotene to create an oleogel offers several health benefits. In the present research, β-carotene-enriched oleogels based on beeswax–MCT oils were characterized with different methods using a Texture analyzer, Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), and differential scanning calorimeter (DSC). This study may provide help to food manufacturers to replace fats with oleogels in commercial applications, such as food and pharmaceutical products.

2. MATERIALS AND METHODS

2.1. Materials

The food-grade beeswax was purchased from Aravali Honey Industries in Rajasthan, India. MCT oil was purchased from Wellversed Health Private Limited, Haryana, India. The 10% β-carotene powder was purchased from Zeushygia Lifesciences Pvt. Ltd., Hyderabad, India. All reagents and chemicals utilized for the research were of analytical grade and procured from Sigma Chemical Co. (St. Louis, MO, USA).

2.2. Preparation of oleogel

The oil phase (MCT oil 95, 90, and 85 g), oleogelator (beeswax 5, 10, and 15 g), and β-carotene (0.2 g/100 g) were combined in a 250 mL flask and stirred magnetically at 500 rpm at 100 °C in a water bath until all gelators were fully dissolved and the mixture became transparent. The mixture was subsequently chilled to 20°C in a water bath for 24 h to yield solid and opaque oleogels. The prepared oleogels were stored at refrigerator temperature for future use.

2.3. Determination of β-carotene

β-carotene extraction was conducted according to the method outlined by Barba et al. (2006) with specific modifications. β-carotene was extracted by immersing 0.5 g of samples in 25 mL of acetone at room temperature in the dark to ensure complete extraction for UV-VIS analysis. The mixture was then subjected to magnetic stirring for 30 min. The extracts were centrifuged to isolate the supernatant, and this process was repeated until the material became completely colorless. The volume was calibrated at 50 mL using the extraction solvents. The absorbance of the extracts was evaluated using a UV-VIS spectrophotometer.

2.3.1. Preparation of β-carotene standard solutions for the UV-Vis method

A standard stock solution of β-carotene at 15 µg/mL was prepared by dissolving 750 µg of β-carotene in a 50 mL volumetric flask filled with acetone. Serial dilutions were conducted from the stock solution to obtain concentrations of 0.1, 0.5, 1.5, 3, 6, 9, and 12 µg/mL of β-carotene. The working solutions were examined within the spectral range of 350–600 nm allocated for this study. The absorption spectra data were collected from the distinctive absorption peak maximum at 453 nm to generate calibration curves.

2.4. Characterization of oleogel

2.4.1. Gel-sol melting temperature of oleogel

The gel-sol melting temperature was determined using the tube inversion method as described by Jadhav et al. (2013). The oleogel was initially contained in a vial, which was subsequently inverted and immersed in a water bath. Then, the water temperature was gradually increased while monitoring the flow of oleogel samples. The temperature at which the oleogel liquefied and flowed was identified as the gel-sol melting point.

2.4.2. Smoke point

The smoke point of MCT oleogel was measured using the method described by Sarwar et al. (2016) with minor modifications. A beaker was filled with 150 g of oleogel and heated until continuous smoke emanated. The temperature was recorded using a digital thermometer.

2.4.3. Free fatty acid and acid value

The free fatty acid content of oleogel was assessed using the Ca 5a-40 technique with minor changes. Approximately 2.0 g of the sample was utilized, dissolved in 25 mL of a 2:1 ether/alcohol solution, along with two drops of a 1% phenolphthalein indicator in ethanol. The mixture was titrated against 0.1 M sodium hydroxide solution in deionized water until a pink hue emerged, maintaining a minimum duration of 30 s (Sharma & Jain, 2015).

2.4.4. Peroxide value

Five grams of sample, 0.5 mL saturated KI solution, and a solvent mixture consisting of acetic acid and chloroform in the ratio 3:2 were mixed per the AOAC technique. Using 1% starch as the indicator, the mixture was titrated against 0.1 mol/L of sodium sulfate.

2.4.5. Water activity

The water activity (aw) of oleogel samples was measured using an AQUALAB 4TE water activity meter (Meter Group, United States). The measurements were performed in triplicate.

2.4.6. Color measurement

The Chroma Meter CR400 (Konica Minolta Sensing Americas, Inc.) was employed to assess the color variation of MCT oleogels. L*, a*, and b* are metrics for lightness, redness/greenness, and yellowness/blueness, respectively. Using the instrument software, the L*, a*, and b* values were obtained.

2.4.7. FTIR

The infrared spectra of the oleogel samples were acquired using a Fourier transform infrared (FTIR) spectrometer. Before each study, the ATR plate was cleaned using analytical-grade isopropyl alcohol. After the background scan, the samples were positioned for FTIR measurement at ambient temperature (15–25 °C). The peaks were examined within a scanning range of 4000–400 cm−1.

2.4.8. Thermal properties

The thermal characteristics of MCT oleogel were examined in comparison to an empty aluminum pan by differential scanning calorimetry, using the methodology established by Pakpahan et al. (2023). The sample (2–4 mg) was positioned in an aluminum pan, sealed, and heated from 30 to 200 °C at a rate of 5 °C/min under a nitrogen flow of 20 mL/min.

2.4.9. X-ray diffraction

The x-ray diffractometer, with a Cu Kα source (λ = 1.54 Å) and operating at 40 kV and 30 mA, was employed to investigate the crystalline structure of oleogel samples. The investigation was conducted within the diffraction angle (2θ) range of 5–50° at ambient temperature, with a step size of 0.02. The XRD patterns were evaluated using software.

2.4.10. Texture profile analysis of oleogel

The textural characteristics of oleogels were assessed using a texture analyzer (TA.XT plus, Stable Micro System Ltd., Surrey, UK) fitted with a 5 kg load cell. Each oleogel sample (100 g) in a 150 mL cylindrical vessel was penetrated with a rod probe (5 mm diameter). The penetration depth and crosshead velocity were 10 mm and 100 mm/min, respectively. The peak force was documented as hardness from the graph of force against time.

3. RESULTS AND DISCUSSION

3.1. Beta-carotene

The β-carotene was added during the making of oleogel with beeswax to increase its nutritional value. β-carotene is a type of provitamin A, a precursor to vitamin A, that the body can convert when needed. The β-carotene content was found to be 122, 124, and 122 µg/100 g for 5, 10, and 15% oleogels, respectively. Some part of the β-carotene is lost during the heating of oleogel preparation. Similar results were provided by Barragán-Martínez et al. (2022). They reported the textural and rheological characteristics of canola oil or beeswax oleogels with varying concentrations of β-carotene (0.0, 0.025, 0.05, 0.1, 0.2, and 0.4 g/100 g) used at different levels. Oleogels containing β-carotene exhibited a more homogenous morphology. The apparent viscosity of the β-carotene erodible hydrogels decreased as a function of increasing shear rate, while the critical strain corresponding to the solid–liquid transition exhibited a significant drop with increasing β-carotene concentration. Moreover, the addition of β-carotene reduced the hardness of the oleogels.

3.2. Gel-sol melting temperature of oleogel

The melting points of MCT oleogels have been shown to increase with the concentration of the gelator. 5% MCT oleogel had a melting point of 51.5 °C, and when the concentration increased to 10%, it reached up to 51.5 °C. It further reached to 55.2 °C when the beeswax concentration was increased to 15%. The melting point of oleogels increased with the increase in concentration, which indicated their stronger intermolecular interactions and greater thermal stability. Similar results for an increase in melting temperature were found by numerous researchers in their studies (Liu et al., 2018; Qu et al., 2024). These properties make MCT oleogels a good option for replacing fats in food, especially in recipes where heat stability is important. A higher melting point makes the oleogel firmer and more stable, improving the texture and overall experience of the food.

3.3. Smoke point

The smoke point is the temperature at which oil begins to smoke continuously and is seen as bluish smoke. This smoke is an indication of the chemical breakdown of fats into glycerol and free fatty acids (FFAs) (Katragadda et al., 2010). The smoke point of MCT oil used in this study was 240 °C, and 5% MCT oleogel has a smoke point of approximately 246 °C, while a 10% MCT oleogel reaches 254 °C, and a 15% MCT oleogel achieves a smoke point of 261 °C. The variations in the smoke point of oleogel are due to the increased concentration of beeswax, which in MCT oil can enhance the thermal stability of the oleogel, making it suitable for high-temperature cooking processes (Shi et al., 2021). According to Chauhan et al. (2022), three different concentrations of oleogels composed of carnauba wax and soybean oil (5, 10, and 15%) were used as frying mediums. The breaking strength of mathri fried in conventional oil (3382.1 g) was found to be higher than that of mathri fried in oleogels (1974.8 g [5% CRW], 1092.7 g [10% CRW], and 3168.1 g [15% CRW]). Also, mathri fried in oleogels absorbed less oil (27.7, 22, and 19.3%, respectively) than those that were fried in oil.

3.4. Free fatty acid (FFA) and acid value

The presence of FFA in MCT oil and beeswax-based oleogels reveals significant disparities in their composition and stability. In 5% MCT oleogel, the FFA value was 0.27%, but in 10% MCT oleogel it markedly increased to 0.80%. This pattern persists with a 15% MCT oleogel, which registers an FFA value of 1.38%. The changes indicate that augmenting the concentration of beeswax in oleogels may result in elevated quantities of FFAs, thereby affecting their sensory and functional characteristics (Dimakopoulou-Papazoglou et al., 2023). Higher FFA value in oils or oleogels affects the flavor, stability, and overall quality, and these parameters are very important in culinary and nutritional purposes. In 5% MCT oleogel, the acid value was found to be 0.55%, whereas 10% MCT oleogel displayed an acid value of 1.60%. The 15% MCT oleogel had a higher acid value (2.76%) than the others. The rise in acid value with increased beeswax concentration suggested that the augmentation of beeswax content in MCT oil heightened acidity in the oleogel formulations, which potentially affected the stability and sensory qualities (Garti & Sato, 2001; Yang et al., 2017). The fatty acid concentration of MCT oils affects the acidity levels because MCTs are prone to hydrolysis, which releases FFAs, raising the general acidity (Duranova et al., 2025). The gel structure depends critically on the presence of beeswax, thereby influencing the acid values (Frolova et al., 2022).

3.5. Peroxide value

The peroxide value of MCT oleogel was 1.75, 1.31, and 1.98 for 5, 10, and 15% oleogel. The peroxide value increased with the increase in the beeswax concentration. Higher concentrations may lead to enhanced oxidative stability in the oleogel formulations (Hamidioglu et al., 2022). The antioxidant properties of beeswax help in oxidation reduction and promote overall stability of the oleogel. Naturally occurring antioxidants and tocopherols in beeswax can help prevent oxidation (Yang et al., 2017). Sobolev et al. (2022) observed that oleogels showed a more complex set of volatiles, with a broader range of ketones, alcohols, and terpenes. The shortest induction period was recorded for the beeswax oleogels. There were strong correlations between oleogel oxidation rate and Young’s modulus (r2 = 0.9511, negative) and the oxidation rate and FFAs concentration (r2 = 0.8195, positive). The data provided showed that fat-based oleogels structured with beeswax fractions have considerable potential for improving oxidation resistance of fat-containing products.

3.6. Water activity of oleogel

The water activity of MCT oil-based oleogels decreases as the concentration increases. The water activities of 5, 10, and 15% oleogels are 0.480, 0.488, and 0.493, respectively. Results show that water activity increases slightly with higher concentrations of MCT oil-based oleogels. The most microbial growth occurs above 0.6 water activity; hence, our oleogel samples are microbiologically stable (Fontana, 2020). MCT oleogels having lower water activity are attractive options in food product development, mainly for products requiring extended shelf life (Perța-Crișan et al., 2022). MCT oils provide several health benefits, such as better energy metabolism and potential weight management effects. When these benefits are combined with reduced water activity, they enhance the functional properties of food products (Watanabe & Tsujino, 2022). Malvano et al. (2022), using a mixture design, investigated the replacement of butter with oleogel from olive oil in plum cake formulations. To obtain a formulation of plum cake with textural and sensory characteristics comparable to the control formulation, a D-optimal mixture design was used. The experimental design evaluated 10 different formulations for hardness, water activity, porosity, and moisture.

3.7. Color measurement

Color measurement of MCT oleogels prepared with 5, 10, and 15% concentrations and their lightness (L*), and red–green (a*), and yellow–blue chromaticity (b*) were determined using a chrome meter. The L* values of 5, 10, and 15% oleogels were 19.96, 19.66, and 19.36, respectively. The values showed a slight decline with increased concentrations, which was due to the increased opacity from denser gel networks at higher structuring agent levels. The a* values for 5, 10, and 15% concentrations were found to be 0.89, 0.88, 0.85, respectively, and the values decreased with increase in beeswax concentration. The b* values of 5, 10, and 15% oleogels were 0.79, 1.13, and 4.91, respectively. This significant increase in the b* value reflects the yellow–blue chromaticity and suggests a shift toward more yellow tones with increased beeswax concentration in oleogel. Previous studies also show that the color of oleogels is affected by the concentration of structuring agents (Dimakopoulou-Papazoglou et al., 2023).

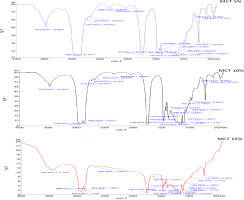

3.8. FTIR

Fourier transform infrared spectroscopy is used to detect the functional groups and interactions contained in substances. The FTIR images of MCT oleogels prepared with 5, 10, and 15% beeswax concentrations are shown in Figure 1. A peak at 3472.09 cm–3 for the 5% MCT oleogel shows O-H stretching, which means there are hydroxyl groups present, probably from water or hydrophilic parts (Garti & Sato, 2001). Peaks at 2924.73 cm–3 and 2731.96 cm–3 are caused by C-H stretching vibrations, which proves that MCT oil and its fatty acid chains are present (Li et al., 2023). The peak at 1741.00 cm–3 shows that the C═O stretching is happening, which means that carbonyl groups are coming from ester functions that are common in lipids (Noonim et al., 2022). More peaks show that C-H is bending and C–O is stretching, which supports the structural stability of oleogel (Yang et al., 2017). There is also a peak at 3472.65 cm–3 for the 10% MCT oleogel that shows O–H stretching (Garti & Sato, 2001). The presence of MCT oil is confirmed by peaks at 2925.38 and 2856.32 cm–3 due to C-H stretching (Zhao et al., 2020). Other peaks at 2732.03 and 2674.97 cm–3 give more information about the hydrocarbon content (Sun et al., 2022). The peak at 1748.39 cm–3–2 is caused by C=O stretching from ester functions (O’Brien, 2004). Some important peaks, like 1464.50 and 1378.87 cm–3 for C-H bending and 1298.06 and 1245.91 cm–3 for C-O stretching, provide more information about the structural makeup. Peaks at 965.38, 723.84, 583.81, and 459.41 cm–3 indicate oleogel-related skeletal motions. The peak at 3467.76 cm–3 in 15% MCT oleogel indicates stretched O-H bonds, indicating hydroxyl groups (Garti & Sato, 2001). Lower wavenumber peaks at 965.14 and 721.88 cm–3 indicate skeletal movement, highlighting the intricate structure of oleogels. Peak value shifts indicate that beeswax concentration may alters oleogel composition. C–H stretching causes peaks at 2956.31, 2922.40, and 2853.06 cm–3, confirming fatty acid chains in MCT oil (Zhao et al., 2020). A peak at 2669.90 cm–3 indicates petroleum concentration. The peak at 1746.12 cm–3 indicates ester functions through C=O stretching. The peak at 1637.71 cm–3 may indicate molecular interactions in the oleogel matrix (O’Brien, 2004). More peaks include the 1464.05, 1418.41, and 1379.12 cm–3 for C-H bending and 1245.73 and 1224.70 cm–3 for C-O stretching. These oleogels reduce trans and saturated fats while maintaining texture and stability, making them good alternatives to fat. In nutrient-rich formulations, baked items, and spreads, their capacity to store and maintain bioactive compounds such as β-carotene makes them more beneficial.

3.9. Thermal properties

The thermal transition characteristics of oleogels with differing percentages of MCT oil exhibit notable variations in their thermal behaviors, as detailed in Figure 2. The onset temperature (To) denotes the initial point of gelation or crystallization, whereas the peak temperature (Tp) indicates the temperature at which maximum heat absorption occurs during the transition. As the MCT concentration escalates from 5 to 15%, To and Tp transition to elevated temperatures. The 5% MCT oleogel exhibits closely aligned To and Tp values, indicating that the gelation or crystallization process transpires within a more restricted temperature range. The 10% MCT oleogel exhibits a greater disparity between To and Tp, signifying a more intricate gelation profile, consistent with the findings of Pakseresht et al. (2023), which examine the impact of triglyceride and fatty acid concentrations on thermal properties, specifically regarding onset and peak temperatures. The 15% MCT oleogel exhibits a notable elevation in Tp, indicating that a higher concentration of MCT oil enhances gelation, presumably due to the augmented quantity of triglyceride molecules that promote intermolecular interactions and thereby stabilizing the gel matrix, as documented by Pang et al. (2020). The conclusion temperature (Tc) denotes the point at which the gel fully melts or crystallization ends. As the concentration of MCT rises, the Tc decreases, with the 15% MCT oleogel exhibiting a lower Tc than the 10 and 5% MCT oleogels. Zampouni et al. (2022) discovered that an increase in the oil proportion inside oleogels resulted in a drop in the melting or transition temperature (Tc), a phenomenon attributable to the diluting effect of the oil on the gel network. The gelatinization enthalpy (ΔH), indicative of the energy necessary for gelation, significantly escalates with MCT content. The ΔH for the 5% MCT oleogel is very low at 4.37 J/g, but it climbs to 10.46 J/g for the 10% MCT oleogel and dramatically rises to 20.79 J/g for the 15% MCT oleogel. The rise in ΔH indicates that greater energy is necessary to disrupt the gel structure as MCT oil content increases, a feature typically associated with the development of more robust or stable networks within the gel matrix. The results correspond with those of who emphasized that elevated lipid concentrations generally lead to enhanced intermolecular forces, necessitating increased energy for gel dissociation. These findings correspond with prior studies emphasizing the impact of MCTs and other gelling agents on the thermal stability and characteristics of oleogels, which are crucial for their use in food and cosmetic goods (Garti & Sato, 2001; Yang et al., 2017).

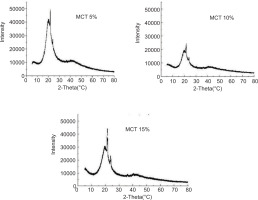

3.10. X-ray diffraction

The crystallization characteristics of MCT oil and beeswax are shown by the distinct diffraction peaks seen in the XRD study of the MCT oleogel formulated with beeswax, as illustrated in Figure 3. In MCT oleogels, the peaks are developed at 21° (β’ phase) and 19.5° (β phase), and an additional peak was observed at 23°. The peak seen at around 21° (2θ), with a similar d-spacing of roughly 4.2 Å, corresponds to the β’ (beta prime) phase, which is associated with the metastable crystal structures in lipid systems. This step is important for the formation of a stable gel network, whereby the uniformly dispersed fat crystals impart the oleogel its smooth texture and essential rheological characteristics. Babu et al. (2022) assert that oleogels composed of MCT oils and natural waxes, such as beeswax, are predisposed to generate the β’ phase due to their rapid cooling rates, which impede the formation of larger crystals.

3.11. Texture profile analysis of oleogel

Firmness is an important textural attribute that influences consumer choices. Firmer textural attributes increase the mouthfeel and overall sensory properties of food products (Perța-Crișan et al., 2023). When comparing the texture values of the different concentrations of MCT oleogels, the firmness values of the 5, 10, and 15% oleogel were 35.29, 50.72, and 299.14 g, respectively (Figure 4). Firmness gives an indication of the hardness of oleogels, and the highest value was obtained in 15% oleogel, which indicates that a product with this type of oleogel provides the most stable and structured texture.

Due to their higher firmness values, oleogels can maintain their shape and consistency when used in making products such as creams, gels, and stable emulsions (Schubert et al., 2022). The stickiness values of the 5, 10, and 15% oleogel were −19.23, −29.02, and −299.14 g, respectively. Higher stickiness values may indicate that the oleogel becomes more cohesive, which can be beneficial in applications where adherence to surfaces is desired (Yılmaz & Öğütcü, 2015). The cohesiveness values of 5, 10, and 15% oleogel were 139.69, 80.96, and 993.91, respectively. The highest cohesiveness value was found in 15% oleogel, which indicated not only its superior firmness but also the significantly enhanced ability to maintain its structure under stress, which is essential in various food and cosmetic applications. The adhesiveness values of 5, 10, and 15% oleogel were −53.02, −24.94, and −121.97, respectively. The highest increase in adhesiveness value was found in 15 % oleogel, which suggested that this oleogel has a stronger capacity to interact with surfaces, which can improve application characteristics in formulations (Liu et al., 2024).

4. CONCLUSION

In this study, the important roles of beeswax and β-carotene-enriched MCT oil-based oleogels are examined. The study shows that MCT oleogels are a good replacement for a fat substitute with enhanced nutritional properties. The addition of β-carotene increases the provitamin A content in oleogels, which promotes healthy skin, prevents night blindness, and encourages bone health. The reduction in water activity levels provides microbiological stability and prolonged shelf life. Textural studies show enhanced hardness, cohesion, and adhesiveness in oleogels. XRD and FTIR measurements validate the establishment of a thick gel network with β and β’ crystalline phases, enhancing structural integrity. The overall study concludes that oleogels made using beeswax and β-carotene are a suitable and health-oriented substitute for conventional fats and can be used in various functional food systems.